Custom Designs

Custom Designs

So far, there has not been an application that we couldn’t tackle! Our team has come across many situations where concepts seemed to be Impossible, but through critical thinking we have come up with clever and unique solutions. We design and manufacture custom systems and tow carts to suit the application.

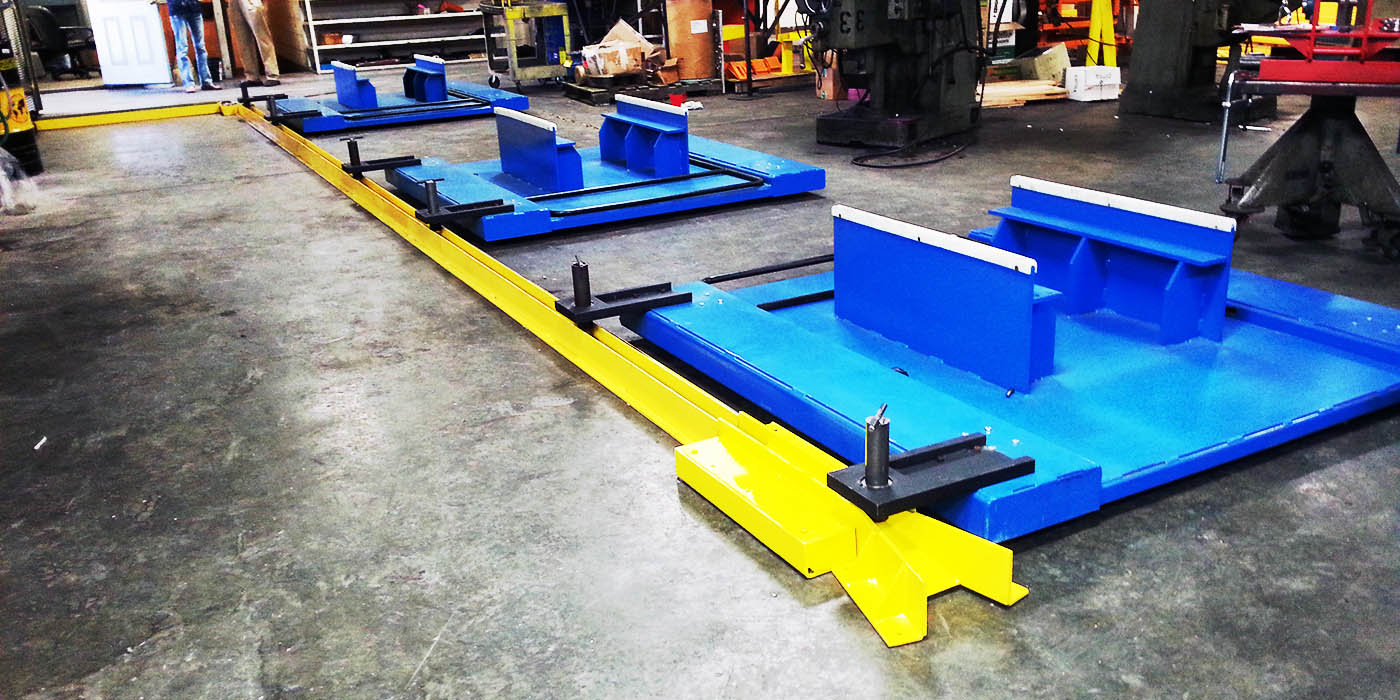

The Side Tow Cart System has become a trend-setter for assembly line applications throughout the states. With the use of Side Pin Tow Carts, this system can be installed with absolutely no concrete work, whatsoever! A side tow system can be routed as a loop or inline. Since the cart is offset from the track, operators can work on 3 sides of the cart without the burden of stepping over the track. Another big advantage to this system is that carts can be pulled off the line with ease. This design is protected by US Patent #9,096,383

Custom Designed Carriers

RSI will work with you and custom design a Tow Cart that will suite your application. Do you need to rotate 5,000 lbs. with one hand–mechanically? We can tell you that this can and has been done by our team. To date, we have not turned away from a project due to “complexity”. We will look at your assembly / material handling process and generate the best possible solution to improve ergonomics and takt time.